Thermoplastic Polyethylene PE Powder Coating

Characteristics

- Excellent acid and alkali resistance, chemical resistance

- Good heat insulation and electrical insulation

- Excellent flexibility and impact resistance

- Good low temperature resistance, no cracking with 400hrs under -30℃,suitable in severe cold environments.

- Non-toxic, comply with requirements of environmental protection.

Use

Refrigerator grids shelf, bicycle basket, stroller, toys, locks, tools, and garden furniture, indoor basket,etc.

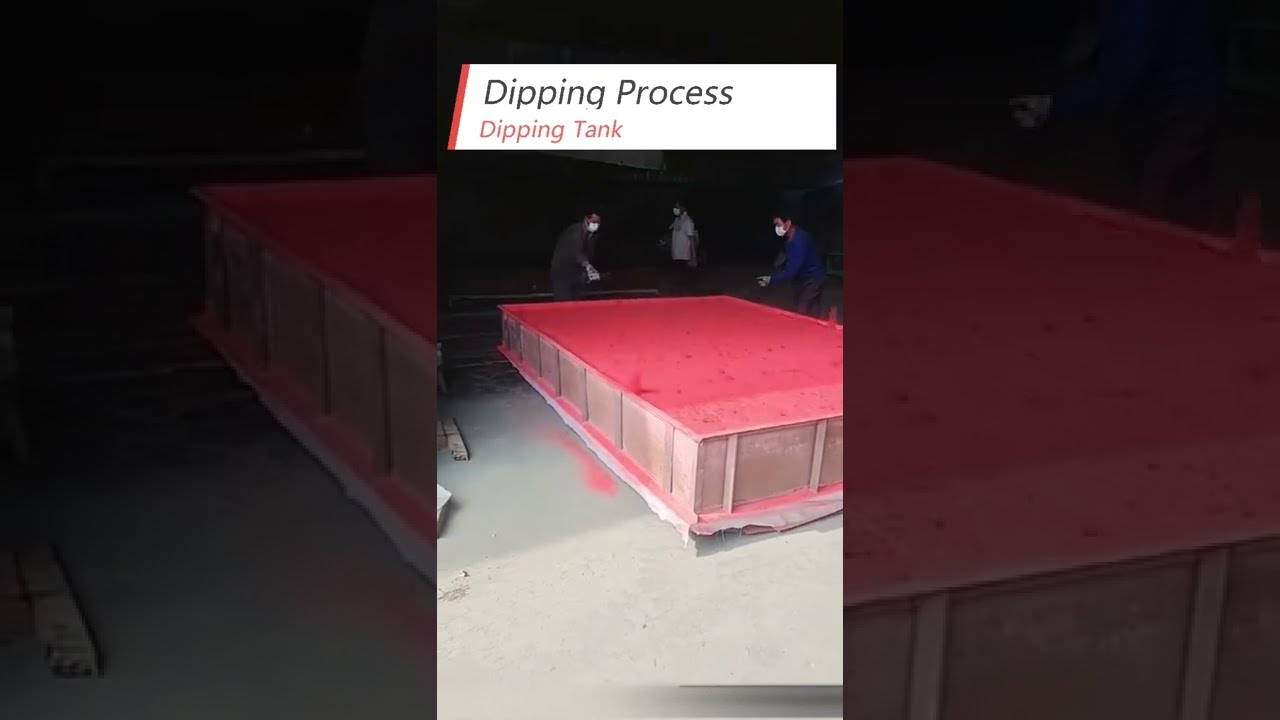

Using Process

- Preheat the work piece up to: 300-400℃

- Then dip work piece into fluidized bed for: 2-3 seconds.

- Put into oven to heat for: 2-5minutes with 200-220℃

The process temperatures used should only be the minimum to achieve an acceptable surface finish. Overheating

may cause the coating to discolour later in storage or in service.

Powder Properties

- Specific Gravity: 0.9-0.92 g/m3,

- Nonvolatile matter: ≥99.5%

- Melt index: 10-50g/10min ,

- Particle size: <300μm

- Packing: 25kg/bag

Coating Properties

- Coating thickness: 200μm- 1200μm

- Appearance: Smooth moderately Glossy

- Hardness: 44-80

- Anti-impack/N.cm > 490

- Chemical resistance: Excellent

Substrate

- Suitable substrate is Iron,Steel,Copper.

- Aluminum, zinc, galvanized,lead are not applicable.

For more information about Polyethylene PE powder coating, please contact us.

How can i get a quote ?

We usually design formula according to customers’ product. So in order to provide you with accurate prices, the following information is necessary.

- What product do you coat? It is better to send us a picture.

- Are they for outdoor use or indoor use?

What is the MOQ ?

- For formal order, the moq is 1000kg, shipping by sea.

- For sample testing, 1-25kg, shipping by air.

What is the packaging method?

25kg/bag, 1ton/pallet, 10-12.5ton/20ft container, 22.5ton/40ft container

What is the delivery time?

2-7 days after receipt of deposit according to the order quantity.

What information should I provide if i want a quote?

The equipment is made-to-order, the following information is necessary if you want to get a quote.

For only dipping tank (fluided bed):

- The max dimension size of the work-piece which you coat

For full set of automatic dipping line( pre-heat oven + dip tank + post-heat oven + conveyer track)

- The max dimension size of the work-piece which you coat .

- The daily output(one day=8hours,one month=30days)

- Heating source type: electric, gas or diesel

- The size of your workshop(length, width and height)

What is the service of after-sale ?

- If there is any problem or failure in use,we are able to assist remotely through the computer network.

- we provide a list of consumables to assist customers in establishing a comprehensive maintenance system.

- our engineers are at your service any time.

- The future development trends of polyethylene powder coating

- What is the HS code of polyethylene powder coating?

- What is the CN number of polyethylene powder?

- What is Polyethylene Paint

- What is High Density Polyethylene

- What is the Production Process of Polyethylene

- What Is Modified Polyethylene ?

- Physical And Chemical Properties of Polyethylene Resin

- What Is General Properties of Polyethylene Resin

- Classification of Polyethylene

- Brief Introduction of Polyethylene Resin